Capabilities

More Cost Effective To Design And Make The Parts In Australia Than Overseas.

"The project required that Archer Enterprises manufacture highly complex stainless steel and titanium components with very fine tolerances including making multiple versions which were fractions of a millimetre different in order to simulate their changing dimensional behaviour under extreme operating temperatures. It was more cost effective to design and make the parts here in Australia with Archer than do it overseas."Research Project Manager Sean McCracken.

Allow Archer to holistically partner with you from the conceptual product design phase right through to manufacture and assembly, or select specific areas of expertise to achieve your desired outcome.

Concept Design / Research & Development

Advanced 3D CAD software

Analysis (FEA, kinematics, etc.)

Concept Design

Fit-for-purpose awareness

Manufacturing/process expertise

R&D

Maintenance, Repair, Overhaul

Mechanical parts, assemblies, machine elements

Re-manufactured parts

Root cause analysis

Engineering Design

Comprehensive technical/specifications/standards library

Mechanical/electromechanical expertise (bearings, transmissions, fluid control, seals, etc.)

Materials expertise

Parametric 3D solid modeling CAD software

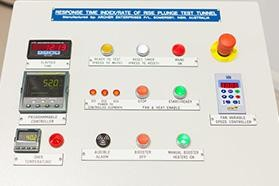

Testing & Analysis

Analysis & reporting

Assemblies, sub-assemblies

Function, stress, cyclical, performance, conformance, etc.

NATA-calibrated equipment

Special-purpose test/analysis equipment

Test lab (hydraulic/pneumatic pressure, vibration, mechanical properties, function)

Engineering & Manufacturing

(CNC) precision machining

Fabrication

Integration of systems, appliances

Painting

Surface preparation

Strategic alliances (foundry, forge, plating, etc.)

Tool, jig & fixture making

Turn-Key “Total Solutions” Partner

Concept to continuous production

Collaborate > Integrate > Assembly > Packaging > Storage > Distribution

Production made-to-order manufacturing